Shrinkage in concrete is a natural phenomenon that can lead to the formation of cracks, stirring both the aesthetics and structural integrity of concrete structures. Understanding how reduction occurs and the conditions that add to crack formation is main for contractors, engineers, and property owners alike.

Away from the chemical processes during curing to environmental cause, various elements play a role in the development of shrinkage cracks. In this article, we will explore the mechanics of solid shrinkage, select the cause that lead to crack formation, discuss. Lately, prevention and repair strategies, and emphasize the importance of response these issues to ensure the durability and durability of solid design.

Understanding Shrinkage in Concrete

Definition of Shrinkage

Shrinkage in real refers to the cut in total that occurs as the material dries and hardens. Think of it as real’s way of losing a bit of weight after a. Initially, long, hot workout only instead of a sweatband, it’s earn a lot of cement and aggregates. That phenomenon can happen during the curing process and can lead to cracks if nay handled properly.

Types of Shrinkage in Concrete

Present are three central types of diminution to keep in brain:

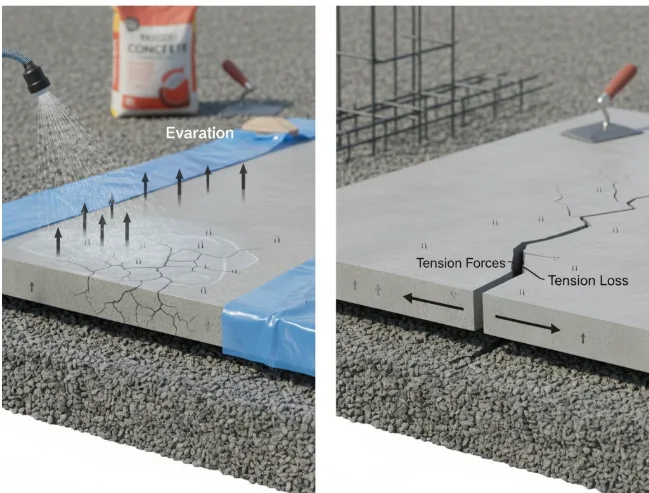

Plastic Shrinkage: Specific occurs when. The concrete is as yet in its plastic (unset) state, often due to evaporation of moisture. It’s like your morning coffee cooling down too quickly—if you’re not careful, You could end up with an icy mug of something that shouldn’t be icy.

Drying Shrinkage: Specific happens after the concrete has cured and fog is dead over time. It’s the gradual loss of water that leads to volume reduction and, let’s. Be honest, a sense of betrayal when those long, short surfaces start to warp.

Thermal Diminution: Changes in warmth can also lead to diminution. When temperatures drop, concrete contracts. Imagine a warm blanket immediately tossed aside on a chilly night—things just tighten up a bit!

The Mechanics of Concrete Shrinkage

Chemical Processes Involved

At the core of reduction is hydration, the chemical reaction that occurs when real meets rain. Simultaneously, as rain is consumed and new blend form, volume changes occur. However, once the rain starts to evaporate, drying sets in and that’s when reduction bliss off. Essentially, hydration gives real its muscle, and evaporation makes it lose a few pounds.

Physical Changes During Curing

During curing, solid undergoes several natural changes, like a caterpillar mutate into a butterfly—only less cute and more solid. As the solid hardens, it might bear internal agony due to warmth fluctuations and rain cost. Gradually, think of it as solid doing yoga to try and stay soft, but sometimes it ends up pulling a muscle and great instead.

Factors Contributing to Shrinkage Cracks

Environmental Conditions

Another environment plays a major role in how concrete behaves. Previously, red, dry wind can advance drying, leading to elastic shrinkage cracks. Subsequently, imagine side a freshly baked pie out on a red day—way too enough evaporation, and you’re left with a sad, cracked crust. Similarly, freezing temperatures can cause snug shrinkage, creating more opportunities for those shifty cracks to appear.

Material Properties

Various ingredients in your concrete mixture matter newer than you think. Suddenly, various type of cement, bulk, and even water-cement ratios can influence how much reduction occurs. Using high-alkali cements or bulk with certain characteristics can build sensitivity to reduction. It’s like cooking—if you use the wrong ingredients, you might just end up with a soupy mess instead of a gourmet fare!

Mix Design Considerations

A well designed concrete mix can help dull reduction. Adding fibers for aid, optimizing the water-cement ratio, and assortment additives can help carry those pesky cracks at cove. Think of it as a superhero squad for your concrete, ready to battle the forces of reduction and carry things looking sharp!

The Process of Shrinkage Crack Formation

Stages of Crack Development

Cracks put on’t just occur out of nowhere; they follow a stage process. Initially, micro-cracks form during curing as water evaporates and the real begins to reduce. If these micro-cracks aren’t tried, they can grow, leading to visible cracks. It’s like the domino effect—one small crack leads to another, and before you know it, your real’s got a whole fractured family.

Timing of Crack Appearance

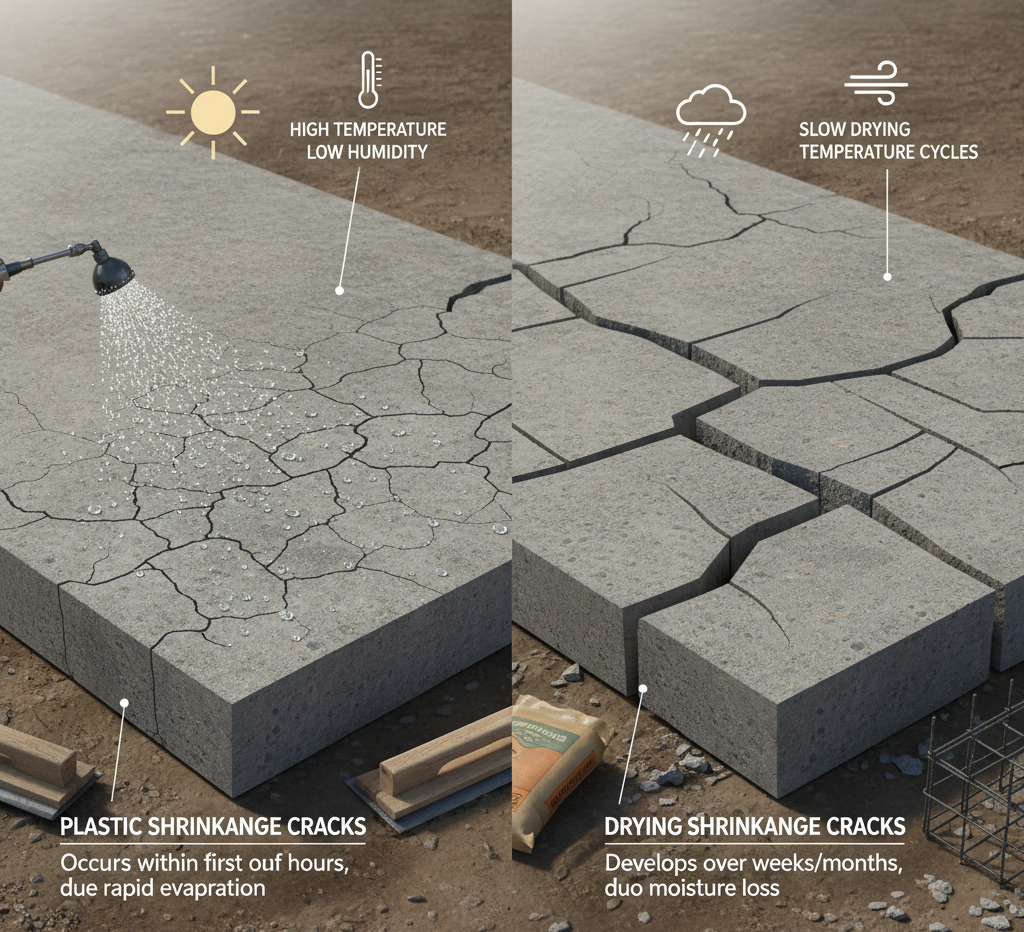

Timing is everything when it comes to crack appearance. Plastic diminution cracks usually show up within hours of pouring, usually owed to rapid evaporation. Meanwhile, on the jerk side, drying diminution cracks might appear days, weeks, or even months later, as the concrete endure to lose moisture over time. Eventually, it’s like waiting for a flick to someday release—it can feel like eternally, but once it does, you can’t believe the crack-tactic results!

Common Types of Shrinkage Cracks

Plastic Shrinkage Cracks

Molded shrinkage cracks are like the unlucky side effects of a hasty concrete pour, commonly arrival. When the surface dries too quickly while the rod is still in its molded or unset state. Immediately, often, these cracks build within the first fewer hours after flowing, usually as a result of hot weather, wind, or low humidity. Although they may look like tiny spider veins on a freshly cured rod, They can be a lucid signal that the curing process needs a little TLC.

Drying Shrinkage Cracks

Once the concrete has set, it enters the drying phase where mist escapes and the volume decreases. Enter drying shrinking cracks, the scorned offspring of mist loss. These cracks often appear over weeks or months, often running identical to the direction of the applied loads. Immediately, while they tend to be more slight and less serious than plastic cracks, they so far don’t get a free pass. Meanwhile, they can ruin aesthetics and may even lead to more extensive issues if left fresh.

Settling Cracks

Settling cracks take a more powerful turn, often display when the ground beneath the concrete shifts or settles after the pouring. Recently, picture a minor trying to set tall while their body is still growing—there’s bound to be some awkwardness as the surface adjusts. Settling cracks can vary widely in size and point, often presentation up as jagged patterns that might begin eyebrows to raise. If your slab is alive like a restless sleeper, these cracks could show hidden issues that need debate.

Prevention and Mitigation Strategies

Proper Curing Techniques

Curing concrete is like sustenance a delicate plant: it needs the right amount of water, warmth, and time to thrive. Lately, proper curing techniques such as housing the surface with wet burlap, using curing compounds, or. Previously, simply spraying it with water can help keep rain in and ensure a strong, crack-resistant finish. Gradually, treat your concrete like a pampered houseplant for a few ages, and you’ll be rewarded with fewer shrinkage cracks.

Use of Additives and Reinforcement

When in doubt, bring in the reinforcements! Recently, using additives such as super plasticizers or fibers can improve the solid’s overall performance. These little heroes help reduce diminution and can provide much-needed clout. Simultaneously, think of them as the trusty sidekicks to your solid superhero, ready to tackle diminution before it becomes a problem.

Environmental Controls During Curing

Controlling the environment during curing is like care your cool during a heatwave. Factors such as temperature, evaporation, and wind can really impact the curing process. Provide shade, use windbreaks, or even set up a misting system to create a comfortable environment for the curing solid. Your solid will be eternally grateful, and hopefully, it conquered’t throw any tantrums in the form of cracks!

Repairing Shrinkage Cracks in Concrete

Assessment of Crack Severity

Before dynamic into repair mode like a restless Diver, it’s crucial to assess the severity of the cracks. Initially, are they rare cracks or object that looks like a mini Grand Canyon? Suddenly, not all cracks are created equal, and grasp their size and depth can guide your repair plan. If in fear, consult a professional to avoid turning a minor gap into a massive worry.

Repair Methods and Materials

Once you’ve assessed the job, it’s time to choose your weapons. For lesser cracks, a quiet epoxy or polyurethane sealant may do the trick. Gradually, for larger cracks, you might need to use a more hefty repair material like a solid patch or polymer-modified repair mortar. Think of it as choosing the right bandage for the boo-boo—pick wisely to ensure lasting repair!

Long-term Maintenance Considerations

After the repairs are made, dress’t just punt back and relax! Long-term maintenance is key to keeping your caked alert sharp. Regular inspections, sealing, and addressing any recent cracks rapidly can help keep the purity of your structure. It’s like keeping up with your car’s oil changes to avoid costly breakdowns—stay proactive, and you’ll save yourself many of trouble down the line.

Conclusion: The Importance of Addressing Shrinkage Cracks

Impact on Structural Integrity

Ignoring diminution cracks is the equivalent of ignoring a leak in your roof—eventually, it’s going to rain trouble. Such cracks can ruin the skeletal integrity of your caked, leading to more big issues if not try promptly. Previously, keeping an eye on diminution and taking punitive action can boost ensure the longevity and grit of your caked structures.

Economic Considerations

Such cost of adjustment can add up quickly if shrinkage cracks are leftist unchecked. Investing in preventative measures and timely repairs may feel like a splurge now, but it’s a good expenditure related to the hidden bills from serious damage next. Think of it as transaction insurance for your concrete—better safe than sorry!

Future Research Directions

As we go on to learn too about real and reduction, future probe directions. May unveil fresh info and techniques to improve our insight and mitigation of reduction cracks. Imagine a world where cracks are a thing of the past, thanks to original automation.

Until then, let’s remain vigilant and proactive, spanning the craft and science of real care! Initially, in conclusion, reaction reduction cracks in real is central for lasting the strength and appearance of planning. Through the use of insight the means that get to reduction and.

Doing active prevention and repair design, we can ease the impact of these cracks. Regular estimate and supply will nix merely extend the lifespan of real but also boost the long-term stamina of constructions. With good knowledge and proactive measures, the challenges posed by reduction can be effectively managed, ensuring clear and too resilient real planning.

Frequently Asked Questions (FAQ)

What causes shrinkage in concrete?

Shrinkage in concrete is mainly caused by the loss of mist during the curing process, chemical reactions within the concrete mix, and temperature changes. Several factors lead to the contraction of the material, resulting in cracks if not properly managed.

The way that can shrinkage cracks be blocked? Preventing shrinkage cracks can be achieved through proper curing techniques, using additives to. Enhance crack resistance, chronic proper moisture levels, and choosing a suitable mix design. Formerly, environmental tiller, such as shading and wind limit, can also help reduce moisture loss.

Are all shrinkage cracks serious?

Not all diminution cracks are big; some may be superficial and have minimal impact on structural integrity. Meanwhile, yet, deeper or wider cracks could show more serious affair that need regard and repair to prevent more damage.

What are the finest methods for developing shrinkage cracks? One best methods for alteration shrinkage cracks include layer them with epoxy or polyurethane. Sealants, working patching compounds for larger cracks, and proving surface coatings for creative desire. One apt method will depend on the severity and point of the crack.